Home » Boiler specification

Manufacture and quality control

Our welding material is certified and will form and part of the tank data package.

Corrosion Prevention

Tanks are fitted with a Magnesium sacrificial anode

Unique to Conrem is that cylinders are Hot-dip galvanized on the inside as well as the outer surfaces, which has proven to give appreciable life to cylinders in various applications.

Hot dip galvanizing provides ideal corrosion protection for steel – no other protective coating matches the unique protection gained by using this process. High adhesion, hard inner layers and a ductile surface layer are among the unique physical properties resulting from this process. Ref: Durban Galvanizing

Cylinder Cladding

Unlike other companies who use a hard-exterior cover, these are designed not to be dented or scratched.

Electrical Boards

These cylinders can be fitted with or without an electrical panel if required. Control panels can be standard housing all switch gear or custom built as per customer requirements.

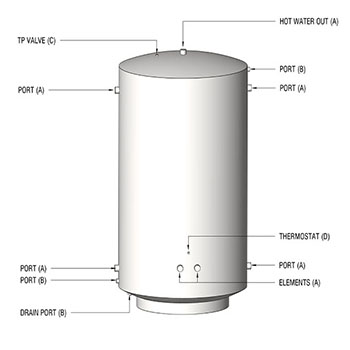

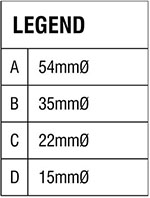

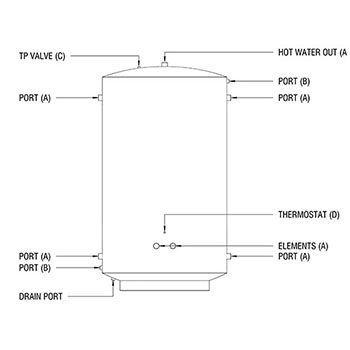

Boiler dimensional layout

Guarantee Terms and Conditions

Our cylinders are guaranteed for a period of 5 years, from the date of installation/sale. This guarantee is subject to Conrem energy’s terms and conditions with pertinent items listed below.